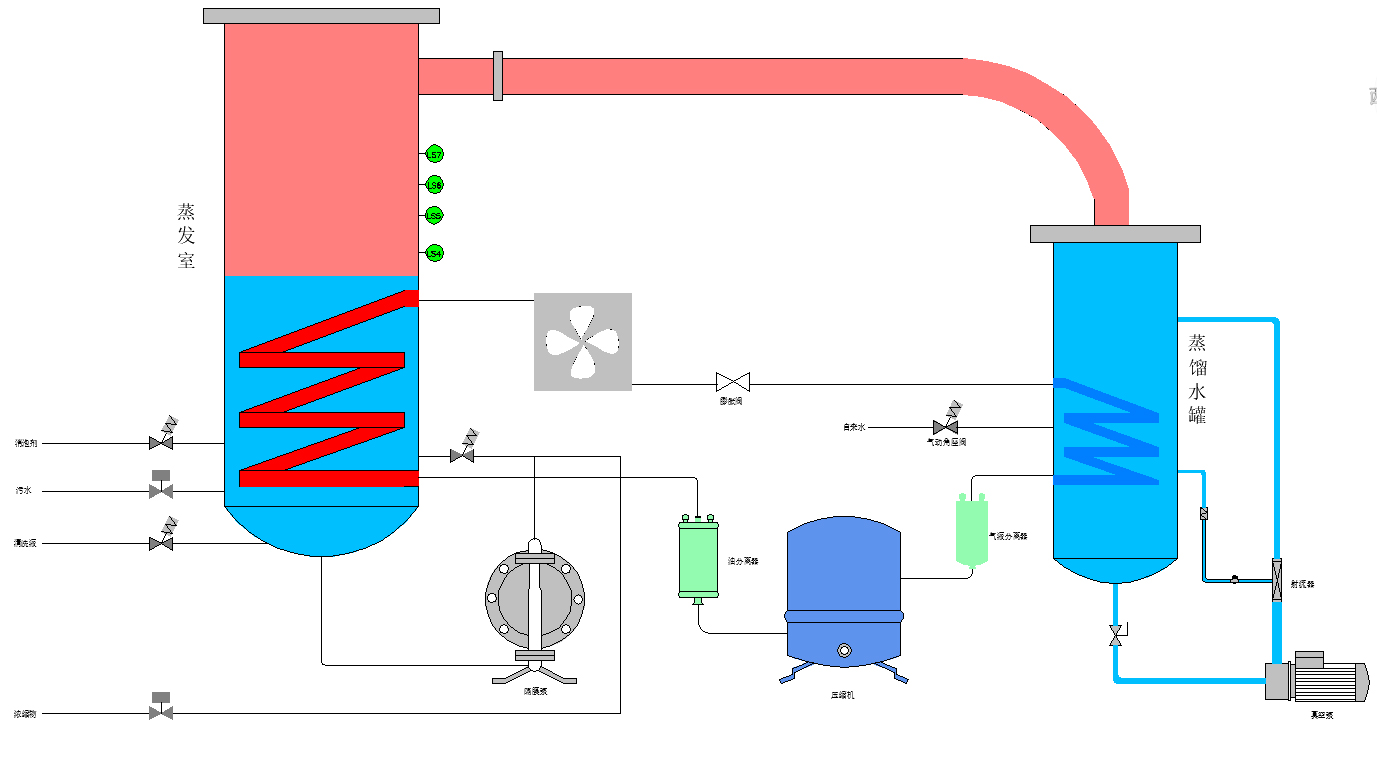

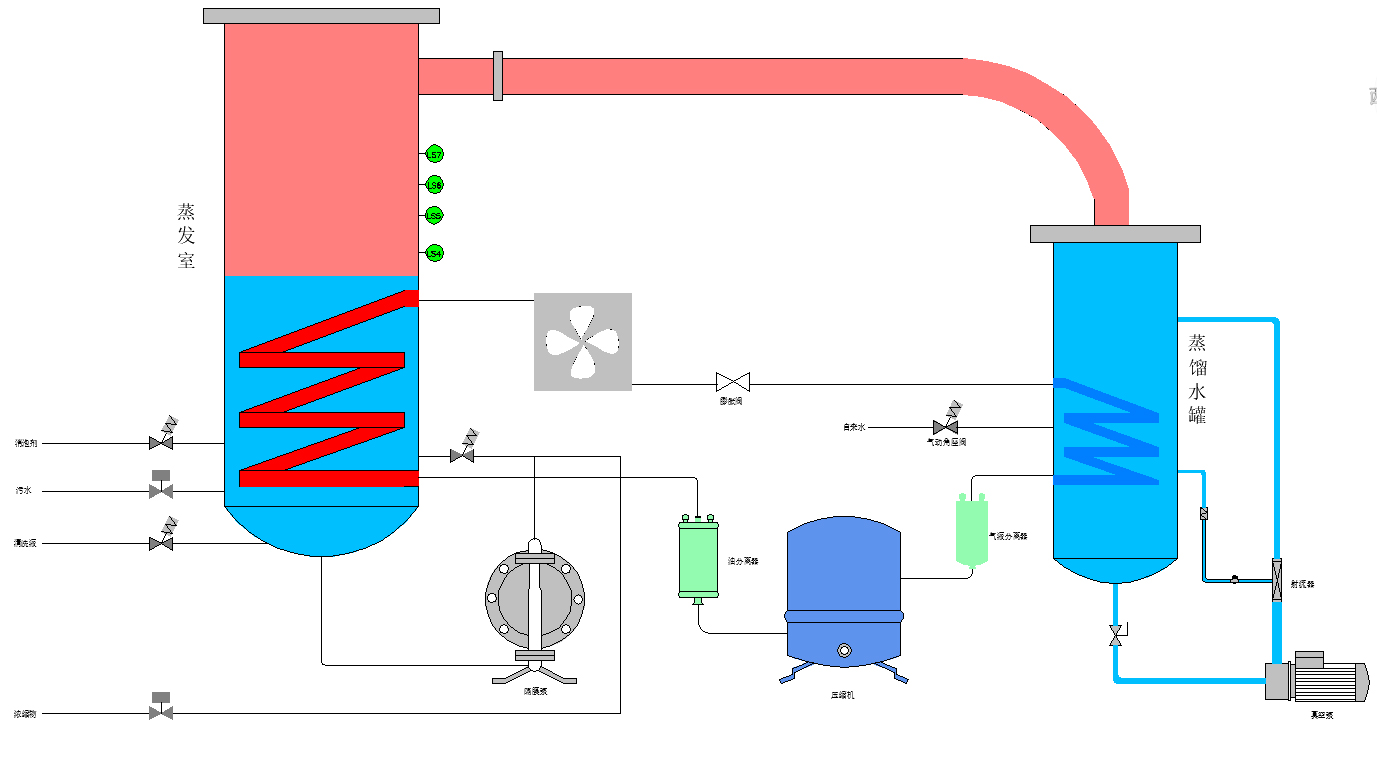

Working principle of low-temperature evaporator:

The jetting device and vacuum pump of the low-temperature evaporator are started, and negative pressure is formed in the tank to discharge materials into the evaporator;

When the sewage enters the working liquid level and the negative pressure reaches the set value, the compressor starts and the system enters heating mode;

Due to the negative pressure inside the tank, the sewage begins to boil when it reaches the boiling point, producing a large amount of water vapor;

➍ Low temperature water vapor enters the condensate tank, is condensed into water by cold coal, reaches a certain value, and is discharged into subsequent distilled water tanks;

Due to the continuous discharge of condensate, the concentration of sewage in the tank gradually increases until it cannot be concentrated, and the concentrated liquid is discharged to the concentrated liquid tank;

The processing capacity and size power of low-temperature evaporator equipment:

The processing capacity and size power of low-temperature evaporator equipment:

| L/Daily processing capacity |

External dimensions: length x width x height (mm) |

Power: (kw * h) |

| 200 |

1450x900x1800 |

3 |

| 300 |

1600x1000x1800 |

5 |

| 500 |

1800x1300x2000 |

7 |

| 1000 |

1950x1400x2000 |

10.5 |

| 2000 |

2000x1700x2100 |

17 |

| 3000 |

2300x1900x2300 |

20 |

The processing capacity and size power of low-temperature evaporator equipment:

The processing capacity and size power of low-temperature evaporator equipment: